In today’s rapidly changing, highly competitive world, product design requires swift translation of human needs and desires into technical specifications for the development of devices and services that meet those needs (Salvador et al. 2013). This calls for a complex integration of qualitative and quantitative data. But despite some notable successes, product design failures are today both extensive and expensive (Anonymous 2015), consuming enormous amounts of time and human labor. Any improvement to the process of product design would be of great public benefit.

Many “smart systems” approaches to the product design process address the problems inherent in this process with limited success. In fact, existing “smart systems” are not very smart. There is an extensive literature available to product designers and engineers addressing lapses in strategies for the successful integration of qualitative and quantitative factors in the design process. It is clear from this body of work that two current problems in product design smart service systems continue to elude researchers.

The first problem is a lack of accurate research focus and systematicity in the determination of relevant qualitative human factors inputs to the design system, expressed as consumer desires. The second is the evaluation of the matching of human factors with potential design features, which can be complex and extensive, in determining the optimum features to emphasize in the product design.

At the University of Minnesota we are working to advance our scientific knowledge of methods for improving smart service systems. First, we are investigating methods of improving the process of integrating qualitative human factors data derived from ethnographic fieldwork conducted by design anthropologists with quantitative data generated by computer and mechanical engineers. Second, we are developing a method for advancing the automation of analysis processes within the smart service system.

In one of our principal projects, we are partnering with a company specializing in the design of medical equipment to improve the design process. The research will both serve the practical need of accelerating a smart service system, and more broadly advance the scientific goals of integrating qualitative and quantitative data processing in the practical transformation of smart service systems.

Existing Systems of Product Design—State of the Art

1. QFD Method

Several well-known systems of product design have been implemented in industry for decades. The best known basic model is the Qualitative Function Deployment System (QFD) developed by Yoji Akao in 1966 (Akao 1990). The QFD System has been widely promulgated with many suggested improvements (Cohen 1995, Bossert 1991, Daetz, Barnard & Norman 1995, Ficalora, Cohen & Cohen 2010). Typical QFD analysis involves correlations between customer needs and desires, and engineering and marketing factors to identify those aspects of design that will best address the original customer needs. QFD analysis is often realized through the construction of a House of Quality—a diagrammatic presentation of all of these factors that results in a “design solution” (Madu 2000, Hauser 1988).

The diagram below is a highly simplified version of a House of Quality analysis for a gear manufacturer. In actual practice the number of factors in any given analysis can number in the hundreds.

The House of Quality analysis, and indeed the entire QFD process, depends heavily on robust qualitative input focusing on human factors derived from consumer research. The entire left-hand section of the diagram consists of qualitative inputs reflecting consumer desires and priorities. The top section consists of potential product features. The match-up between product features and consumer desires is reflected in the intersecting matrix in the middle of the diagram, the match-ups being weighted on an algorithmic scale to show strong vs. weak priorities. The entire diagram is then analyzed by trained designers, who essentially “eyeball” the diagram and make intuitive product design decisions based on their expert judgments.

2. Kano Model

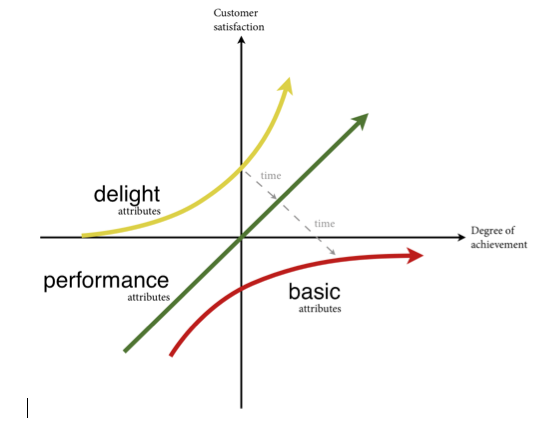

The Kano Model was developed by Noriaki Kano in the 1960s to assess product development and customer satisfaction (Kano et al. 1984). The Kano Model posits that there are three attributes of a product that govern consumer satisfaction: performance attributes, basic attributes and delight attributes. Customer satisfaction will be higher as performance increases. If performance is low, customer satisfaction will also be low. Basic attributes are attributes that customers expect to be present in a product. If they are present, customers are satisfied but their presence will not be noticed because they are expected to be present. If they are absent, customer assessment will be low. Delight attributes are attributes that, when present are unexpected, and give customers “delight.” If they are absent, customers may not notice, because they are not expected. Kano notes that over time delight attributes come to be expected, and thus change into basic factors (Jones 1995, Matsushita, Kijima 2014, Cadotte, Turgeon 1988).

As with the QFD system, the Kano model relies on expert judgment from product designers to determine the performance, basic and delight factors, as well as the time lags that convert delight factors into basic factors. These judgments may be based on consumer research, but such research is rarely systematic.

3. The CENSYS™ Service System

The CENSYS™ system combines features of both QFD analysis and the Kano Method and embodies their three basic factors:

- basic functionality

- competitive viability

- “customer delight”

The first factor is fundamental for any design process, and it is generally achievable by product engineers who create products that “work.” The second factor requires more effort working directly with customers and end users. Even a product design that is functional may not be competitive for a number of reasons: it may be inappropriately sized, clumsy to implement, unaesthetic, or either ignore or fail to achieve customer needs in a multitude of other ways. The third factor is the most elusive. A design that is truly successful creates “customer delight.” It sparks the imagination and intrigues the mind, delivering more than the customer expects.

CENSYS™ continues to be a functional smart service system. It represents an innovative advance over the well-established Quality Function Deployment (QFD) system, which has been in use since the 1960s, as mentioned above. At present, although the CENSYS™ system provides a somewhat greater degree of weighting of human factor considerations than previously available and is already to some extent a smart service system, its creators emphasize that it has limitations. Qualitative data is elicited in a less than systematic manner. It is highly dependent on the informed intuition of its developers in determining qualitative inputs and weighting of potential product design factors. Moreover, it requires expert interpretation to generate the product design results. Like all existing product design service systems, it could be greatly improved.

Interdisciplinary Research

Several product design service systems have long incorporated human factors determination as a primary qualitative initial input for the design process. However, a rigorous methodology for determining these factors may be haphazard or incomplete. To aims to address these issues, we are working with one existing system that incorporates many of the properties of many other service systems currently in use.

We were excited when we saw that problems in the product design service system process reflect a broader problem in science and social science—integrating qualitative and quantitative data for the design of practical systems. Thus our project is a fortuitous opportunity for interdisciplinary collaboration to solve a pressing human need. We began to collaborate with colleagues in computer science and mechanical engineering to work toward a more robust product design system. Our interdisciplinary team was formed accomplish two goals.

First, using a robust ethnographic process to assess the existing system, the team plans to generate a substantially richer array of human factor components to inform the design process. Ethnographic research has only recently been introduced in the design process. It involves extensive contact with consumers to determine the cultural, social and personal meaning a given product or process acquires in their lives. This is accomplished through standard ethnographic techniques properly employed—intensive observation over a long period of time, eliciting personal narrative, unstructured interviews and comparisons between multiple consumers to determine broad patterns of attitudes and cultural meaning. This process, like all ethnographic research, is designed to determine the needs and desires of consumers of which they are themselves unaware. EPIC people will recognize that the process is frequently described as “making the invisible visible.” Some of the most successful product designers advocate strongly for its use (Brown, Katz 2009, Kelley, Littman 2005, Kelley, Littman 2001, Lockwood 2010, Madsbjerg, Rasmussen 2014, Griffin 1993), but few have developed it to its full potential in the design process (Kimbell 2014, Ladner 2014, Levine 1992, DiCarlo, McGowan & Rottenberg 2014, Sunderland, Denny 2007).

The second goal of our research team is to develop a set of algorithms that will serve as the basis for automating the CENSYS™ evaluation process, which will enable CENSYS™ to “learn” as it generates increasingly successful results. This will be achieved through the development of data mining and management algorithms that will better evaluate the relative importance of individual potential design features as selected from a large array of matchings of consumer wants and needs with those potential design features. The resulting set of algorithms will represent a significant advance over product design processes that currently exist.

An Emerging Research Methodology

1. Ethnographic Methods—Design Anthropology

All product design systems depend on understanding what customers truly desire in the products they consume. The fundamental difficulty faced by designers is that customers frequently don’t know what they desire themselves. This creates an informational vacuum where more sophisticated aspects of competitive viability are unknown, and where the elements that create “consumer delight” are also unknown.

The most important needs and desires of consumers exist at an unarticulated level. Ethnographic research into the design process is the basis for design anthropology, which helps achieve the elusive goal of discovering what it is that consumers truly desire in a new product or service, what will make the product competitive and what will delight consumers and inspire them to acquire and use the product. Ethnography as a methodology aims to “make the invisible visible.” Discovering these needs through intense ethnographic engagement with human factors in their natural social and cultural context is the basic aim of design anthropology.

Product designers as well as others in the business world often fail to understand ethnography as a methodology. Frequently ethnography is used as a buzz word for loose engagement with consumers. In design publications the qualitative research needed for analytic methods such as QFD, Kano or CENSYS™ may be called ethnography, but it frequently consists of a few interviews with a limited number of people, or short sessions with a focus group conducted by individuals with no real ethnographic training (Madsbjerg, Rasmussen 2014, Kimbell 2014, Ladner 2014, Sunderland, Denny 2007, Denny, Sunderland 2014). Such research also misses a fundamental point: the real basis for understanding consumer desires lies not in individual preferences, but in the broad cultural patterns in which products are embedded. Ethnography focuses on explicating the meaning of a given material product in the life experiences of members of a society as a whole. Only through this extensive holistic analysis can an accurate representation of consumer desires be formulated

2. Developing Solutions for Judging Weighting Factors for Product Design

As important as the human factors qualitative data are to the design process, translating them into quantifiable weighting factors for decision making in the design process has been difficult. In the three examples of product design systems described above, in the end specific product design decisions rely heavily on expert judgment and intuition, the analytic techniques of these systems largely serving as guidelines. The results may be widely variable from project to project depending on the personnel involved. We are working to help sharpen this transition from data to reliable and effective decisions in the design process. This work will serve both the practical needs of moving an existing smart service system toward greater speed, accuracy and self-government; and the broader goal of advancing the scientific goals of integrating qualitative and quantitative data processing in the practical transformation of smart service systems.

Our Research

We adopted two hypotheses. First, existing product development systems can be made more effective through the implementation of a robust ethnographic strategy to generate human factors not considered by manufacturers relating to the design process for any proposed product. Here we are striving to develop a set of ethnographic investigation procedures generalizable for the determination of these human factors in the implementation of existing product design systems. Second, the evaluation system embodied in product design systems can be automated through data management and mining techniques to produce consistent, definitive conclusions that will be reliable and less dependent on single expert interpreters.

Through this process, product design systems will approach a self-governing ideal, generating improvements in their own service system and efficiency in generating successful design strategies leading to successful products that meet the three requirements specified in the system: basic functionality, competitive viability and “customer delight.”

Broader Impact: Better Human Centered Design

Designers have long been moving toward more human centered processes. Design firms such as Worrell and IDEO have been highly successful through implementing this innovation philosophy. Design anthropology has emerged as a profession to aid in the qualitative aspects of this innovation process. Worrell’s CENSYS™ service system was created to facilitate and enhance the viability of newly designed and innovative solutions. While it has been highly successful, it still requires a great deal of subjective expert judgment both in the determination of human factors inputs and in the interpretation of the analytic scoring system.

Product design has been one of the lifeblood economic activities of the US economy in the 20th and 21st centuries. Although it has yielded great economic and manufacturing successes, these successes come at great cost in finances and human effort. Outsized product development budgets result from inefficiencies in the design process: research methodologies fail to identify real consumer needs and data management practices fail to identify product design features that address those needs. This is an economic problem, a business problem and a public policy problem.

We hope that our research will address these weaknesses in current product design practice by providing improvements in product design service systems. Robust qualitative human factors data collection methods will be developed to solve the problem of inadequate identification of consumer needs and desires. Robust data management and mining practices will allow for more accurate prediction of successful design products. In the best of all possible worlds, our research will result in commercially viable methods that will benefit the product design industry and, by extension, the economic and material well-being of humans throughout the world.

References

Anonymous. 2015 “Top 25 Biggest Product Flops of All Time”, 2015, Daily Finance, [Online], pp. 10 Jan 2015. Available from: http://www.dailyfinance.com/photos/top-25-biggest-product-flops-of-all-time/. [10 Jan 2015].

Akao, Y. 1990, Quality function deployment: integrating customer requirements into product design, Productivity Press, Cambridge, Mass.

Belk, R.W. 2006, Handbook of qualitative research methods in marketing, Edward Elgar, Cheltenham, UK; Northampton, Mass.

Blyth, S. & Kimbell, L. 2011, Design Thinking and the Big Society, Actant and Taylor Haig, London.

Bossert, J.L. 1991, Quality function deployment: a practitioner’s approach, ASQC Quality Press; M. Dekker, Milwaukee, Wis.; New York.

Brown, T. & Katz, B. 2009, Change by design: how design thinking transforms organizations and inspires innovation, 1st edn, Harper Business, New York.

Cadotte, E. & Turgeon, N. 1988, “Dissatisfiers and satisfiers: suggestions from consumer complaints and compliments”, Journal of Consumer Satisfaction, Dissatisfaction and Complaining Behavior, vol. 1, pp. 74-79.

Cohen, L. 1995, Quality function deployment: how to make QFD work for you, Addison-Wesley, Reading, Mass.

Daetz, D., Barnard, W. & Norman, R. 1995, Customer integration: the quality function deployment (QFD) leader’s guide for decision making, Wiley, New York.

Denny, R.M. & Sunderland, P.L. 2014, Handbook of anthropology in business, Left Coast Press, Walnut Creek, California.

DiCarlo, L., McGowan, H. & Rottenberg, S. 2014, “Anthropology in a Design, Engineering and Commerce Curriculum” in Handbook of Anthropology in Business, eds. R. Denny & P. Sunderland, Left Coast Press, Walnut Creek, California, pp. 247-265.

Ficalora, J.P., Cohen, L. & Cohen, L. 2010, Quality function deployment and Six Sigma: a QFD handbook, 2nd edn, Prentice Hall, Upper Saddle River, NJ.

Fragnière, E., Nanchen, B. & Sitten, M. 2012, “Performing Service Design Experiments Using Ethnomethodology and Theatre-Based Reenactment: A Swiss Ski Resort Case Study”, Service Science, vol. 4, no. 2, pp. 89-100.

Griffin, A. 1993, “The Voice of the Customer”, Marketing science, vol. 12, no. 1, pp. 1-27.

Haik, Y. & Shahin, T.M.M. 2011, Engineering design process, 2nd edn, Cengage Learning, Stamford, Conn.

Hauser, J.R. 1988, “The House of Quality”, Harvard business review, vol. 66, no. 3, pp. 63-73.

Jones, T.O. 1995, “Why satisfied customers defect”, Harvard business review, vol. 73, no. 6, pp. 88-99.

Kano, N., Nobuhiku Seraku, Fumio Takahashi & Shinichi Tsuji 1984, ” Attractive quality and must-be quality”, Journal of the Japanese Society for Quality Control (in Japanese), vol. 14, no. 2, pp. 39-48.

Kelley, T. & Littman, J. 2005, The ten faces of innovation: IDEO’s strategies for beating the devil’s advocate & driving creativity throughout your organization, Currency/Doubleday, New York.

Kelley, T. & Littman, J. 2001, The art of innovation: lessons in creativity from IDEO, America’s leading design firm, 1st edn, Currency/Doubleday, New York.

Kimbell, L. 2014, “Design Ethnography, Public Policy, & Public Services: Rendering Collective Issues Doable & at Human Scale” in Handbook of Anthropology in Business, eds. P. Sunderland & R. Denny, Left Coast Press, pp. 186-201.

Ladner, S. 2014, Practical ethnography: a guide to doing ethnography in the private sector, Left Coast Press, Walnut Creek, Calif.

Lafley, A.G. & Charan, R. 2008, The game-changer: how you can drive revenue and profit growth with innovation, 1st edn, Crown Business, New York.

Levine, G. 1992, “Anthropologists in Adland”, Advertising Age, , pp. 3-49.

Lockwood, T. 2010, Design thinking: integrating innovation, customer experience and brand value, Allworth Press, New York.

Madsbjerg, C. & Rasmussen, M.B. 2014, The moment of clarity: using the human sciences to solve your hardest business problems, Harvard Business Review Press, Boston, Massachusetts.

Madu, C.N. 2000, House of quality (QFD) in a minute, Chi Publishers, Fairfield, Conn.

Matsushita, H. & Kijima, K. 2014, “Value-in-Context of Healthcare: What Human Factors Differentiate Quality of Nursing Services?”, Service Science, vol. 6, no. 3, pp. 149-160.

Pelto, P.J. 2013; 2013, Applied ethnography: guidelines for field research, Left Coast Press, Inc., Walnut Creek, Calif.

Salvador, T., Anderson, K., Barnett, B., Beckwith, R., Bezaitis, M., Falkner, S.A., Healey, J., Hirsch, T., Kitner, K.R., Mainwaring, S.D., Nafus, D., Sherry, J. & Zafiroglu, A. 2013, Radical Flux, Intel Press, Portland, OR.

Sunderland, P.L. & Denny, R.M.T. 2007, Doing anthropology in consumer research, Left Coast Press, Walnut Creek, Calif.

0 Comments